Introduction to Product Principle

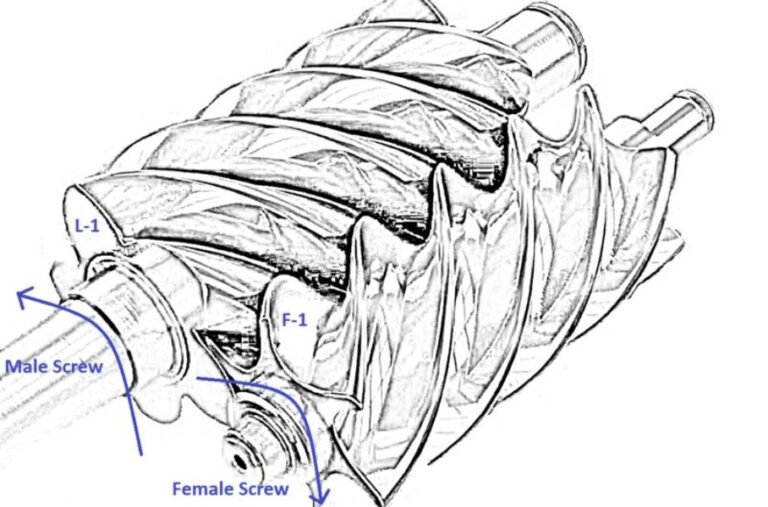

The oil-free water-lubricated single-stage screw compressors operates using a unique design that relies on two interlocking rotors to compress air without the use of oil. Water serves as the lubricant, ensuring that the compressor operates smoothly while minimizing environmental impact. This innovative approach allows for cleaner air output, making it ideal for applications where oil contamination is unacceptable.

Advantages of Our Product

At Tianli Air Compressor Manufacturing, we pride ourselves on offering high-quality oil-free water-lubricated screw compressors that stand out in the market. Here are some of the key advantages of our products:

Environmental Responsibility: By utilizing water for lubrication, our compressors significantly reduce the carbon footprint and avoid the disposal issues associated with oil.

- Enhanced Efficiency: Our compressors deliver consistent performance with optimal energy savings, providing higher air output while consuming less power.

- Low Maintenance Costs: The simpler design of our compressors results in fewer moving parts, translating to lower maintenance requirements and extended service life.

- Reliable Performance: Engineered with precision, our compressors maintain stable pressure levels and ensure high-quality air delivery for various industrial applications.

OEM/ODM Services

We understand that each customer has unique requirements. Therefore, Tianli offers OEM and ODM services to meet your specific needs. Our experienced engineering team is ready to collaborate with you to develop customized solutions that align with your operational goals. From design to production, we ensure that our products meet the highest industry standards while reflecting your brand identity.

Comparison with Oil-Free Scroll Compressors

While both oil-free water-lubricated screw compressors and oil-free scroll compressors serve the same fundamental purpose of providing clean air, they differ significantly in several aspects:

- Performance: Screw compressors generally offer higher flow rates and are suitable for larger industrial applications. In contrast, scroll compressors are better suited for smaller, lower-capacity applications.

- Efficiency: Screw compressors can achieve better efficiency at higher loads, while scroll compressors excel in quieter operations and are typically more compact.

- Cost: The initial investment for screw compressors may be higher due to their complexity, but their long-term operational costs can be lower due to their efficiency and durability.

Product Applications

Our oil-free water-lubricated single-stage screw compressors are versatile and widely applicable across various industries, including:

- Food and Beverage: Ensuring clean, oil-free air for processing and packaging.

- Pharmaceuticals: Meeting stringent cleanliness standards for manufacturing.

- Textiles: Providing reliable air supply for machinery and equipment.

- Electronics: Protecting sensitive components from contamination.

Conclusion

Tianli Air Compressor Manufacturing is committed to providing cutting-edge oil-free water-lubricated screw compressors that meet the evolving needs of our customers. Our focus on quality, efficiency, and customization makes us a preferred partner in the industry.

For a closer look at our products, please check out our video on YouTube: Tianli Air Compressors.

What Size Air Compressor Do I Need? How To Choose the Right Size for Your Job

Air compressors, sometimes called pneumatic compressors, draw energy from pressurized air and use it to power air tools. Whether you lead a construction team or perform home repairs, compressors are a great power source. While air tools are generally safe, misusing subpar equipment can lead to injury or death. The best way to

How Air Compressors Work: An Animated Guide

Air compressors are versatile and vital components of any factory or workshop. They’ve become smaller and less bulky in recent years, making them more usable in various work situations. These are highly useful portable machines that power single air tools. The main advantage of air compressors is that they’re much

China’s Global Contribution to Manufacturing

China has developed a comprehensive industrial system, marked by intense competition in various market segments. Through competitive growth, Chinese companies have amassed valuable experience and have transformed their product and service advantages into international trade partnerships. In fact, Chinese-made products provide essential conditions for countries to participate in global trade

11 Key Considerations for Selecting a PET Air Compressor System

When it comes to producing polyethylene terephthalate (PET) products, the selection of an appropriate air compressor system is crucial. The efficiency, reliability, and quality of compressed air can significantly impact the overall production process. Here are 11 key considerations to keep in mind when selecting a PET air compressor system.

Oil-Free Water-Lubricated Single-Stage Screw Compressor: A Comprehensive Overview

Introduction to Product Principle The oil-free water-lubricated single-stage screw compressors operates using a unique design that relies on two interlocking rotors to compress air without the use of oil. Water serves as the lubricant, ensuring that the compressor operates smoothly while minimizing environmental impact. This innovative approach allows for cleaner

Tips for Choosing the right Piston Compressor for Your Needs

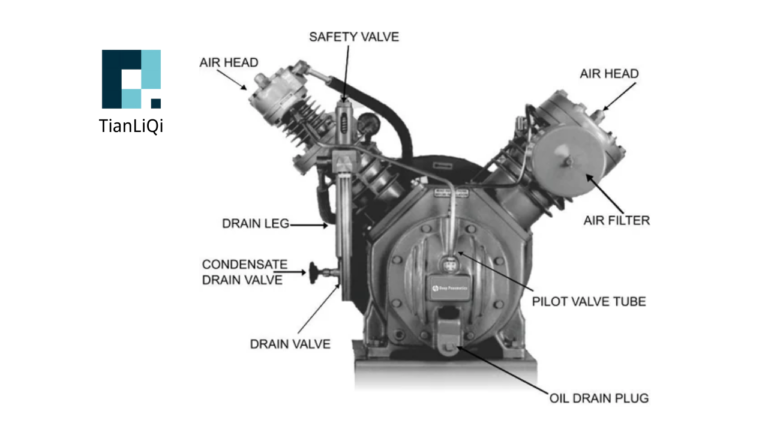

Piston compressors are extensively used in a variety of industries and applications to efficiently compress and store air for powering tools or machinery. Selecting the right compressor can be overwhelming if you’re not well-versed in the different types and specifications. This comprehensive buying guide will delve into crucial factors such

Screw Compressor Working Principle

twin-screw-refined Table of Contents Screw Compressor Working Principle There are many types of screw compressors in terms of the number of screws used to compress the gas. If a screw compressor contains a single screw, it is called a single-screw compressor; similarly, for two screws, it is called a twin-screw

-768x432.png)

Exploring the Inner Workings of a Piston Air Compressor: A Detailed Analysis

Piston air compressors are indispensable tools in various industries, powering a wide array of pneumatic devices and systems. However, understanding the intricate components and mechanisms within these compressors can provide valuable insights into their operation and maintenance. Let’s take a closer look at the inner workings of a piston air

Exploring Piston Compressors: Operation, Applications, and Variations

Piston compressors play a pivotal role in various industries, employing displacement compression to elevate gas or air pressure for diverse applications. Let’s delve into how piston compressors function, their applications, and the different types available. Understanding Piston Compressors: Piston compressors operate based on displacement compression, a fundamental principle in air