When it comes to producing polyethylene terephthalate (PET) products, the selection of an appropriate air compressor system is crucial. The efficiency, reliability, and quality of compressed air can significantly impact the overall production process. Here are 11 key considerations to keep in mind when selecting a PET air compressor system.

Types of PET Air Compressor Systems

PET air systems started out with three-stage, air-cooled, lubricated piston units in multiple quantities for smaller systems and water-cooled, oil-free, three-stage or two-stage boosters for the larger systems. Over the last ten years, four-stage centrifugals have become a popular base-load air compressor, and smaller companies have embraced air-cooled, single-stage lubricated boosters. The king of the hill is still the three-stage, water-cooled, oil-free piston machine.

Here is a recap of the types of blow air compressors that are available today:

- Three-Stage Lubricated Air-Cooled Piston—15/40 CFM; lubricated only; compresses from atmospheric to 580 psi; maximum flow 40/80 CFM each, so it must be used in multiples; provides backup; good space utilization; moderately efficient; 10- to 12-year service life; very cost-effective for small systems

- Single-Stage Boosters — 10/500 CFM; available in lubricated and non-lubricated configurations; uses existing or required inlet air from 125 to 175 psi, depending on pressure; moderate space utilization; reasonably efficient; 10- to 15-year service life; very cost-effective solution to provide PET compressed air

- Single-Stage Boosters — 600/2,000 CFM; normally oil-free and water-cooled; uses 125 psi inlet air; low rpm; requires large space; fairly efficient; moderately high-cost; 20- to 30-year service life; used where a large amount of low pressure air is available; realistic costs for large systems

- High-Pressure Four-Stage Centrifugal — 1,800/5,000 CFM; oil-free; space-efficient; power cost inefficient unless full load; long periods of low maintenance with costly major rebuild; moderate cost per CFM; 10- to 15-year service life; realistic choice for base-load in large systems

- Three-Stage Water-Cooled Piston — 90/1400 CFM; oil-free; water-cooled; reasonably space efficient spending on configuration; most efficient option; can be high on maintenance costs if routine checks are not done at 4,000 to 6,000 hours; highest investment cost per CFM; 20- to 30-year service life; staple of most large production PET plant compressor systems

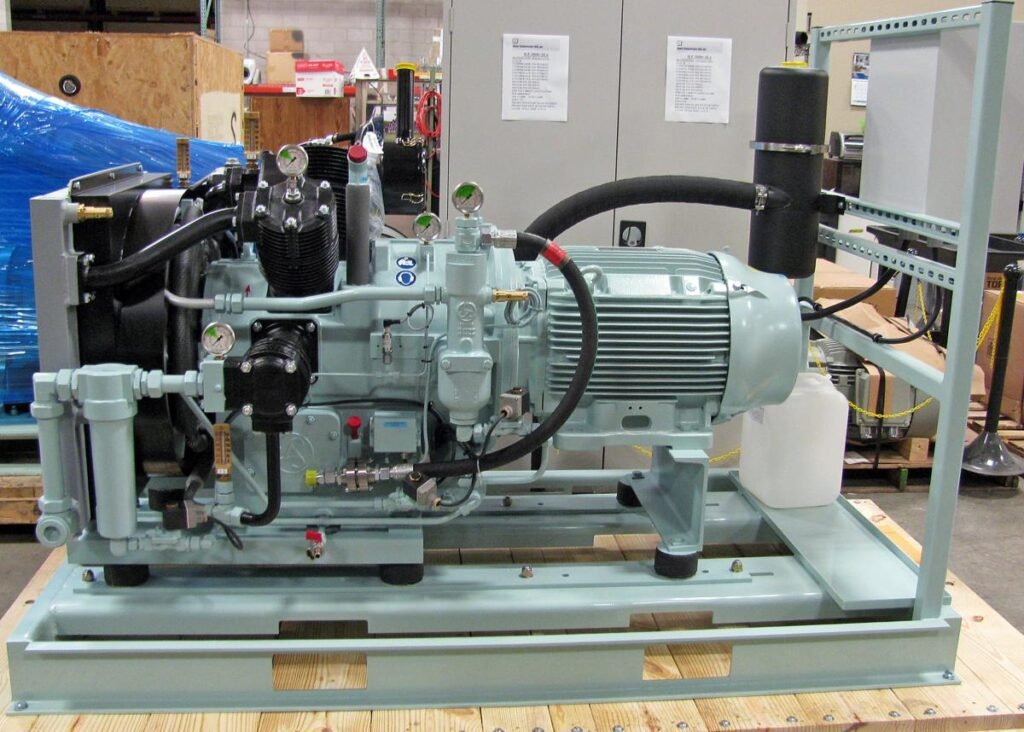

Three-stage, oil-free, water-cooled piston air compressor and high-pressure refrigerated air dryer for PET systems from AF Compressors.

Three-stage-reciprocating-piston-high-pressure-air-compressor-for-PET

Single-stage boosters have a long service life and are a cost-effective solution for smaller PET bottling applications.

Defining Blow Air Requirements

Now that we know what equipment is available, we can evaluate some of the other aspects of determining which compressed air system makes the most sense for various plant applications. Based on the best practices gathered from over 15 years of experience, here are 11 key things to consider when defining the blow air requirements for your application.

1. Type of Compressor

Choosing the right type of compressor is fundamental. There are primarily two types: piston and rotary screw compressors. Piston compressors are suitable for lower volume applications, while rotary screw compressors are ideal for continuous operation and higher air demands, making them a preferred choice for PET applications.

2. Air Quality Requirements

PET manufacturing processes often require high-quality, clean air. Oil-free air compressors or oil-free scroll compressors should be considered to avoid contamination, as even small amounts of oil can affect product quality.

3. Pressure Requirements

Evaluate the specific pressure needs of your PET production process. Different applications may require varying pressure levels. Ensure that the compressor can meet these demands without compromising efficiency.

4. Flow Rate

The flow rate of the compressor should match the air demand of your PET production line. Calculate the required cubic feet per minute (CFM) to ensure that the compressor can provide sufficient air supply without delays or bottlenecks.

5. Energy Efficiency

Energy costs can significantly impact your operational budget. Look for compressors with high energy efficiency ratings. Variable speed drives (VSD) can also help optimize energy consumption by adjusting the compressor’s output to match demand.

6. Maintenance Requirements

Consider the maintenance needs of the compressor system. Regular maintenance is essential for ensuring longevity and optimal performance. Choose a compressor with easy access to components for maintenance and a robust service network.

7. Size and Space Constraints

Evaluate the available space in your facility. The size of the compressor and its ancillary equipment must fit within your production area. Compact designs may be necessary for facilities with limited space.

8. Noise Levels

Compressed air systems can generate significant noise. If your production area is close to workspaces or residential areas, consider low-noise compressor options or sound enclosures to minimize disturbance.

9. Integration with Existing Systems

Ensure that the new compressor system can seamlessly integrate with your existing production line. Compatibility with other equipment and controls is essential for efficient operation.

10. Cost of Ownership

While initial purchase price is important, consider the total cost of ownership, including maintenance, energy consumption, and potential downtime. A higher upfront investment in a reliable, efficient compressor can lead to lower operating costs in the long run.

11. Manufacturer Reputation and Support

Finally, research the manufacturer’s reputation in the industry. A reputable manufacturer will offer reliable products and good customer support. Ensure they provide adequate technical support and warranty options to safeguard your investment.

Conclusion

Selecting the right PET air compressor system is a multifaceted decision that can influence production efficiency, product quality, and operational costs. By considering these 11 key factors, you can make a more informed decision that aligns with your specific production needs. Always consult with industry experts and compressor manufacturers to tailor a solution that best fits your operational requirements.

By focusing on these considerations, you can ensure a reliable and efficient air compressor system that enhances your PET production process.

For more information contact Ethan luo